Lehui 60,000CPH beer canning line , the first high-speed canning line manufacturing in China, put into production at Heineken Brewery(Zhejiang) CO., Ltd. In 1st, Nov 2015, with feature of high efficiency and automation.

LEHUI R&D

-108 valve flowmeter electronic valve can filler:

Feature of High level De-palletizer:

-The top frame and inter layer paper of high level de-palletizer are removed and magazine automatically , empty pallet as well.

-Adopting by PLC control, with improvement of accurate movements.

-Motor drive applied into pallet lifting system, help with stability.

-Fully electro pneumatic protection including lifting position locker, can stopper, wrong hright pallet reject, collision protector, oil temperature alarm, muting system for pallet feeding.

Empty can conveyor choose SystemPlast lubrication free belt, open top grid belt, brings smooth and stable conveying , low abrasion and energy saving.

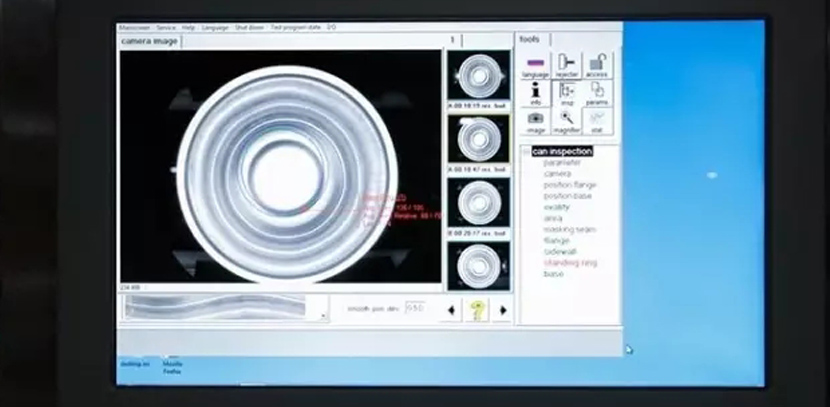

Empty Can Inspector

Empty cans pass the inspection unit on a regular conveyor. A light sensor in the camera head reports a camera trigger signal as soon as it is by can. The reject system mounted behind the inspection unit.

The rinser frame, pippings and fittings are using Stainless steel 304. The inside surface of cans are thoroughly cleaned by specialized high pressure spray nozzle, which is stainless steel solid wimble. It equipped with wide transparent windows and fallen can rejecting. The rinsing water will be collected and reused.

-All filing processes are controlled by PLC, including air replacement, CO2 back pressure, filling, pressure relief,

- Capacity 60000CPH(330ml)

- Filling accuracy sigma 1.2ml

- Equipment Efficiency≥90%

- The qualification rate of filling accuracy≥99%

- Can loss rate≤0.02%

- Oxygen pickup≤20ppb

Core technology: Electronic fluid filling mechanism, Patent number: 201210449093.7, obtaining National Invention Patents in 2012.

Seamer

As a most critical machine in Canning line, The 8-head seamer is selected.

The end unwrapped feeder is supplied by CSW Holland. It contains approximately 30 rolls 202 ends, this is 30 minutes storage calculated by 600 cans per minute and 600 ends per roll.

-Adopted by single deck belt system tunnel pasteurizer;

-Energy saving central heating design;

-Main conveying belt using intralox modular plastic belt;

-Achieving equally spraying by using round piping fitted with spray nozzles;

-The full can conveyor using (System Plast) lubarication free belt,

-The complete line adopted by VFD pressure free control to reduce the crush and scratch between cans ;

-Dynamic transfer design for all 90 degree transfer;

-With function of blow drying .

Wrap Around Packer

Full cases discharged from packer travel along on roller conveyor, turn to shot side leading pass through weighing check, the low weight case rejected, then apply hot melt anti slip drips on the top of cartons, entering into palletizer.

Auto-Palletizer, the finished goods is delivered to the warehouse by forklift.

After the SAT(site acceptance test), each machine are operating well, Lehui team works hard with their consummate skill , it our please to be praised in writing by Heineken project manager in Netherland.

-

Super large Longmen processing center put into use

The super

large gantry processing center, which is suitable for aviation, ae...

Super large Longmen processing center put into use

The super

large gantry processing center, which is suitable for aviation, ae...

-

LEHUI International Packaging Machinery Research Institute started a new journey of development

Under

the planning and leadership of Huang Dongning, chairman of LEHUI Inter...

LEHUI International Packaging Machinery Research Institute started a new journey of development

Under

the planning and leadership of Huang Dongning, chairman of LEHUI Inter...

-

Well-grounded GrandPak PET Cold Aseptic Packaging Line

PET bottle cold aseptic filling refers to the product sterilized at high tempera...

Well-grounded GrandPak PET Cold Aseptic Packaging Line

PET bottle cold aseptic filling refers to the product sterilized at high tempera...

-

A tip for you to identify the quality of beverage

Because of their simple production process, low requirements f...

A tip for you to identify the quality of beverage

Because of their simple production process, low requirements f...