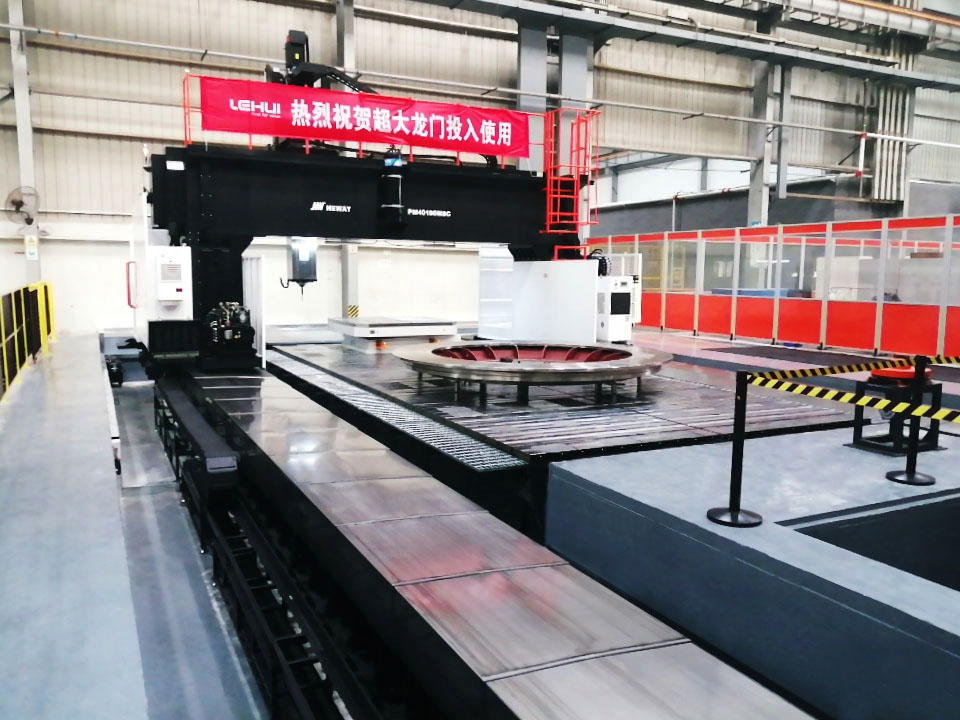

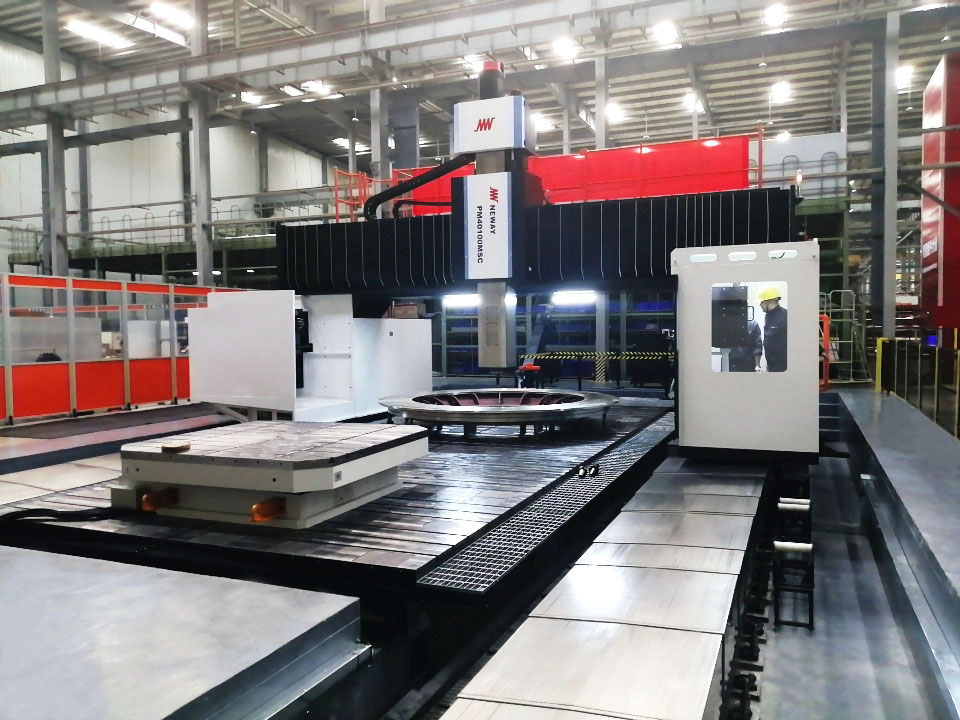

The super large gantry processing center, which is suitable for aviation, aerospace, energy and other industries, is officially started in GrandPak. In the future, it will process all kinds of large high-speed filling equipment parts for liquid food packaging equipment, such as platform, canning cylinder, air chamber distribution ring, rotary table and other large precision parts. Its X axis up to 10 meters, Y axis can actually be processed to 5.6 meters of large machine space, which can be excellent to complete the processing task of more complex parts.

The introduction of the super large gantry processing center not only large torque, high speed and low noise characteristics, fully meet the boring and milling, drilling and other processing needs, in addition to high rigidity and stability of precision to ensure high torque cutting precision machining, especially suitable for spindle elongation of strong milling, large hole boring and the use of Angle head of the five side processing.

"As an equipment manufacturing enterprise, if it wants to achieve sustainable progress and sound development, it needs to adhere to two basic concepts, one is that the product is king, the other is to focus on core technology." Attaching great importance to technology research and development and the introduction of high precision processing equipment, GrandPak is exceeding the standard to meet customer needs on the road to constantly break through innovation, excellence.

-

LEHUI International Packaging Machinery Research Institute started a new journey of development

Under

the planning and leadership of Huang Dongning, chairman of LEHUI Inter...

LEHUI International Packaging Machinery Research Institute started a new journey of development

Under

the planning and leadership of Huang Dongning, chairman of LEHUI Inter...

-

Well-grounded GrandPak PET Cold Aseptic Packaging Line

PET bottle cold aseptic filling refers to the product sterilized at high tempera...

Well-grounded GrandPak PET Cold Aseptic Packaging Line

PET bottle cold aseptic filling refers to the product sterilized at high tempera...

-

A tip for you to identify the quality of beverage

Because of their simple production process, low requirements f...

A tip for you to identify the quality of beverage

Because of their simple production process, low requirements f...